All About Liquid Chlorine with Terry Arko of HASA

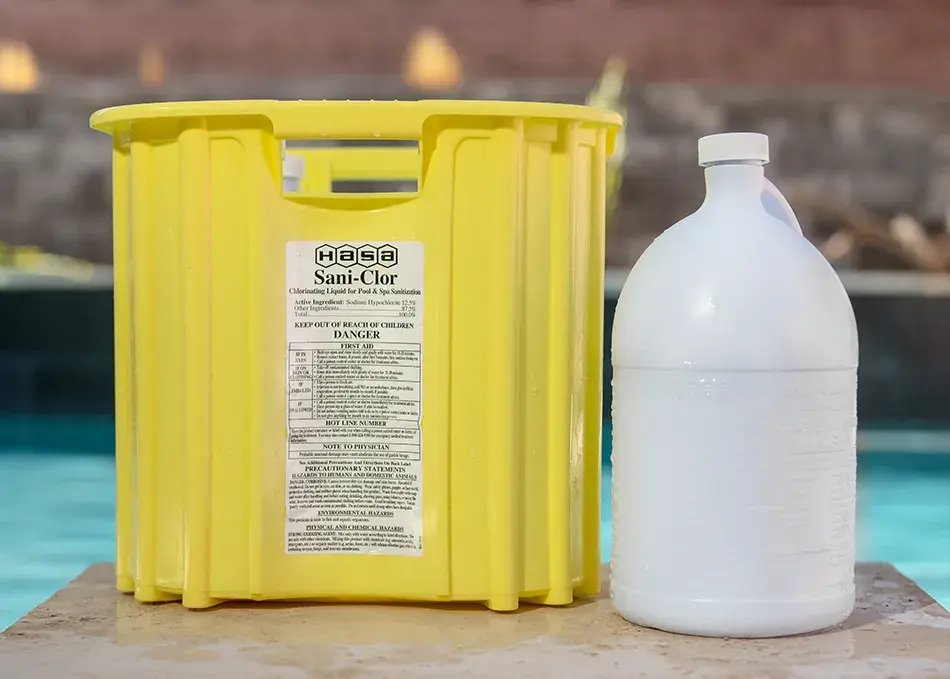

HASA is a big provider of liquid chlorine in my region and the familiar yellow cases and white bottles are available at local pool stores as...

⬢ Pool Professionals

Professional-grade products. Expert support. Built for your business.

⬢ Pool Owners

Eco-friendly, easy-to-use solutions to keep your pool clean and clear.

⬢ Industrial

Efficient treatment & supply. Performance-focused operations support.

⬢ Municipal

Reliable solutions & delivery. Sustainable treatment for public systems.

⬢ Dealers

Help your pool & spa customers with trusted, professional-grade products.

⬢ Pool Products

HASA has the chlorine, algaecides, and sanitizers you need to keep your pool or spa clean and clear.

⬢ Hot Tub Products

Shop our full line of Hi-Temp spa care products, including Eco-Safe Clarifiers and pH Increasers.

⬢ Ancillary Products

Our eco-friendly water treatments are science-backed and purposefully focused.

⬢ Mini-Bulk Program

We deliver a premium 12.5% sodium hypochlorite solution for sanitizing commercial pools and large-scale water systems.

⬢ Blog

Learn from water chemistry experts.

⬢ Videos

Browse instructional how-to videos.

⬢ Safety Data Sheets

Download SDS sheets for HASA products.

⬢ Pool Chemical Calculator

Achieve balanced chemistry easily.

⬢ Liquid Chlorine For Pools

A service professional’s guide that's been made simple.

⬢ Orenda Academy

For water chemistry & professional pool management knowledge.

⬢ Events

Find HASA at an event near you.

⬢ Rewards

Explore our HASA loyalty rewards program.

⬢ About HASA

Learn about HASA's commitment via the returnable packaging model.

⬢ Careers

Explore open positions with HASA.

In today’s recreational water industry, there are three main types of chlorine used to disinfect, oxidize and leave protective residuals in swimming pool water.

All these forms of chlorine provide Free Available Chlorine (FAC) at differing levels and are good at disinfecting, oxidizing and creating a residual. However, some quick comparisons show that liquid chlorine has more advantages including performance, water conservation and safety.

Cal Hypo—ppm of FAC supplied by 1lbs. in 10,000 gallons

Trichlor—ppm of FAC supplied by 1lbs. in 10,000 gallons = 11 ppm

Liquid Chlorine—ppm of FAC supplied from 1 gallon in 10,000 gallons

It is important to note that FAC makes up the effective disinfecting and oxidative power of chlorine in water.

Cal Hypo: Every pound needed for proper FAC increases the calcium hardness by 8 ppm. High calcium hardness levels lead to increased pH, total alkalinity, total dissolved solids (TDS) and damaging forms of calcium scale. Increased calcium also leads to cloudy pool water, clogged filters, heat exchanger failure, poor circulation and rough pool surfaces. Water must be drained frequently to lower the build up of calcium from regular cal hypo use. Acceptable target levels for calcium hardness in pools are 200-400 ppm.

Trichlor: Because trichlor is a stabilized organic form of chlorine, the by-product of regular use is increased levels of cyanuric acid (CYA). Increased levels of CYA can reduce the effectiveness of disinfection from chlorine in pool water. Levels that exceed 60 ppm CYA will interfere with total alkalinity TA testing, leading to false high TA readings. There will be increased TDS as well. Because trichlor has a very low pH of 2.8, it WILL lower pH and total alkalinity. For this reason, sodium carbonate (soda ash) may have to be used to raise pH, which can also lead to a marked increase of TDS. Acceptable target levels of CYA are 30-50 ppm. Many commercial codes state a maximum level of no more than 100-150 ppm. The only practical method for lowering of CYA level is to drain pool water. The amount of water needed to drain a 10,000-gallon pool to lower the CYA from 100 ppm to 30 ppm is 7,000 gallons.

For commercial facilities, both calcium and CYA levels are regulated so facilities must drain and dilute frequently to remain in compliance and to prevent damage to equipment and pool surfaces. This can lead to additional cost in water and sewage.

Liquid Chlorine: Because liquid chlorine is a non-stabilized inorganic form of chlorine, it will not contribute CYA to the pool. Also, it will not directly increase calcium hardness levels. So, there are no detrimental by-products from the use of liquid chlorine that would lead to increased draining of the pool. While liquid chlorine will increase TDS, it is only in the form of chloride salts, which do not present the need for regulated draining like calcium and CYA. Also, because it is in a liquid form, the dissolution of chlorine is far greater than the solid forms of cal hypo and trichlor even in high TDS conditions. Pound for pound, you get the highest amount of pure chlorine from a gallon of 12.5% liquid sodium hypochlorite compared to cal hypo or trichlor.

Pounds of pure chlorine:

Cal Hypo: Classified as a class 3 oxidizer. Highly reactive and flammable. Also, not recommended for use in vinyl liner, fiberglass, painted or colored plaster pools due to possible bleaching. Improper storage and disposal methods can lead to extreme reactions such as fire and explosion. Increased levels of calcium in heated pools can lead to the precipitation of calcium with carbonate to create damaging scale on heat exchangers.

Trichlor: Is flammable when in contact with certain organic materials or contaminants. Contamination with moisture, organic matter or other chemicals will start a chemical reaction and generate heat, hazardous gas, possible fire and explosion. Improper use of trichlor tablets in a pool skimmer can lead to damaging corrosive situations such as corrosion of copper piping and heat exchangers. Product added directly to vinyl liners can lead to bleaching, wrinkling and shrinkage. Will lower pH and total alkalinity requiring the use of sodium carbonate or sodium bicarbonate. Can bleach fiberglass, painted or colored plaster, if used directly.

Liquid Chlorine: Non-flammable, non-combustible and non-explosive. Care should be taken to prevent direct contact of liquid with eyes or skin; use gloves and goggles when applying. Store properly in non-corrosive containers in a cool, dark, well-ventilated area. Liquid chlorine can be used in vinyl, fiberglass, painted and colored plaster pools. There are no adverse effects or bleaching when added properly in deep end of pool with circulation running. There are no detrimental by-products from the addition of liquid chlorine. Liquid chlorine is an effective sanitizer and oxidizer that is economical, convenient and easy to handle.

HASA is a big provider of liquid chlorine in my region and the familiar yellow cases and white bottles are available at local pool stores as...

Pool Ownership Without the Overload. Owning a pool should enhance your lifestyle—not overwhelm it. And yet for many homeowners, keeping pool water...

1 min read

As recently published by HASA’s Terry Arko in Aqua Magazine Defining what liquid sodium hypochlorite is-it isn’t liquid chlorine In the swimming pool...